Bold design for badass cleaning equipment

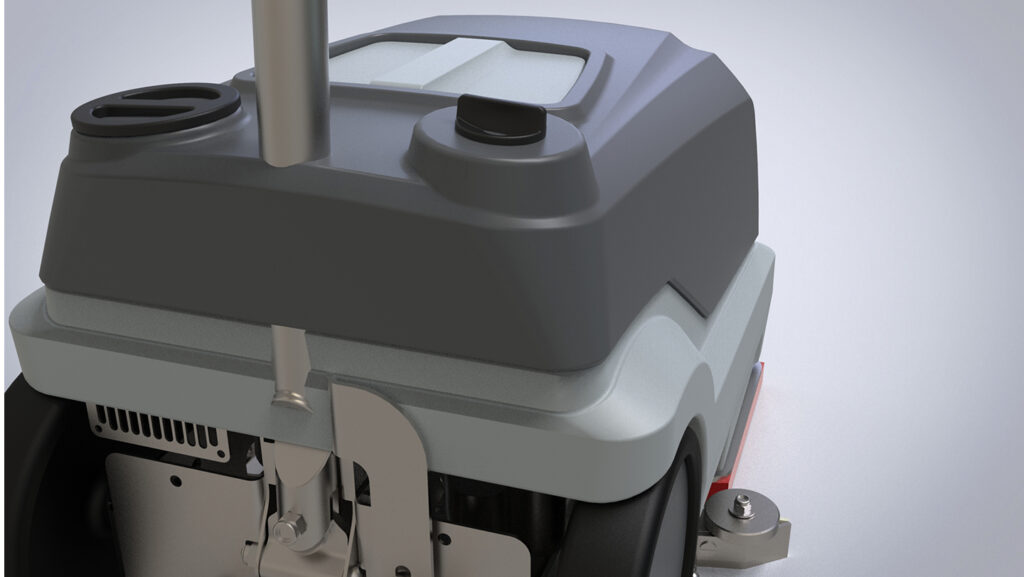

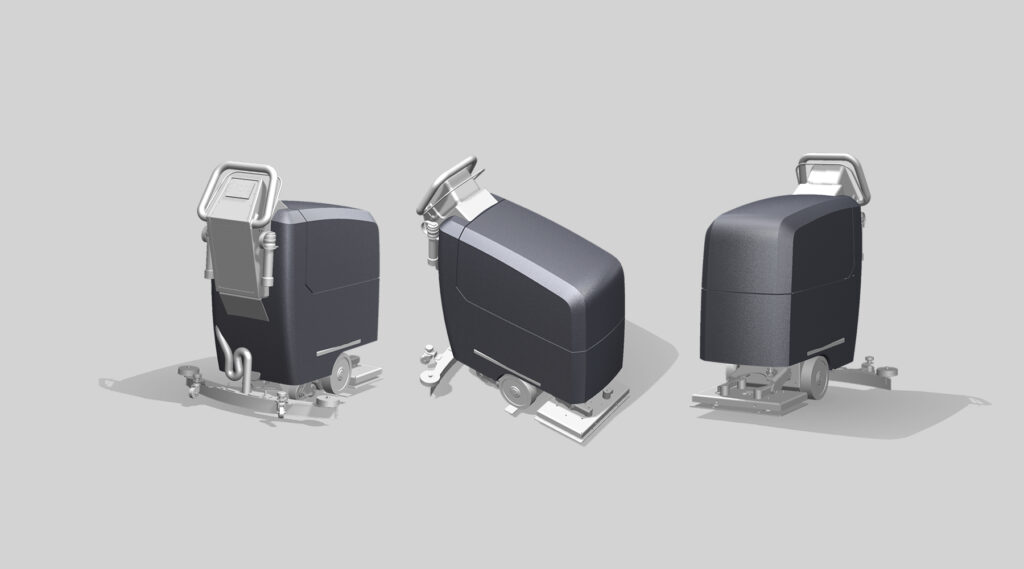

The collaboration with Excentr involved expanding their professional cleaning equipment line with integrated fluid management. Leading the end-to-end design, design strategy and plastic engineering, I focused on functionality, brand consistency and manufacturability.

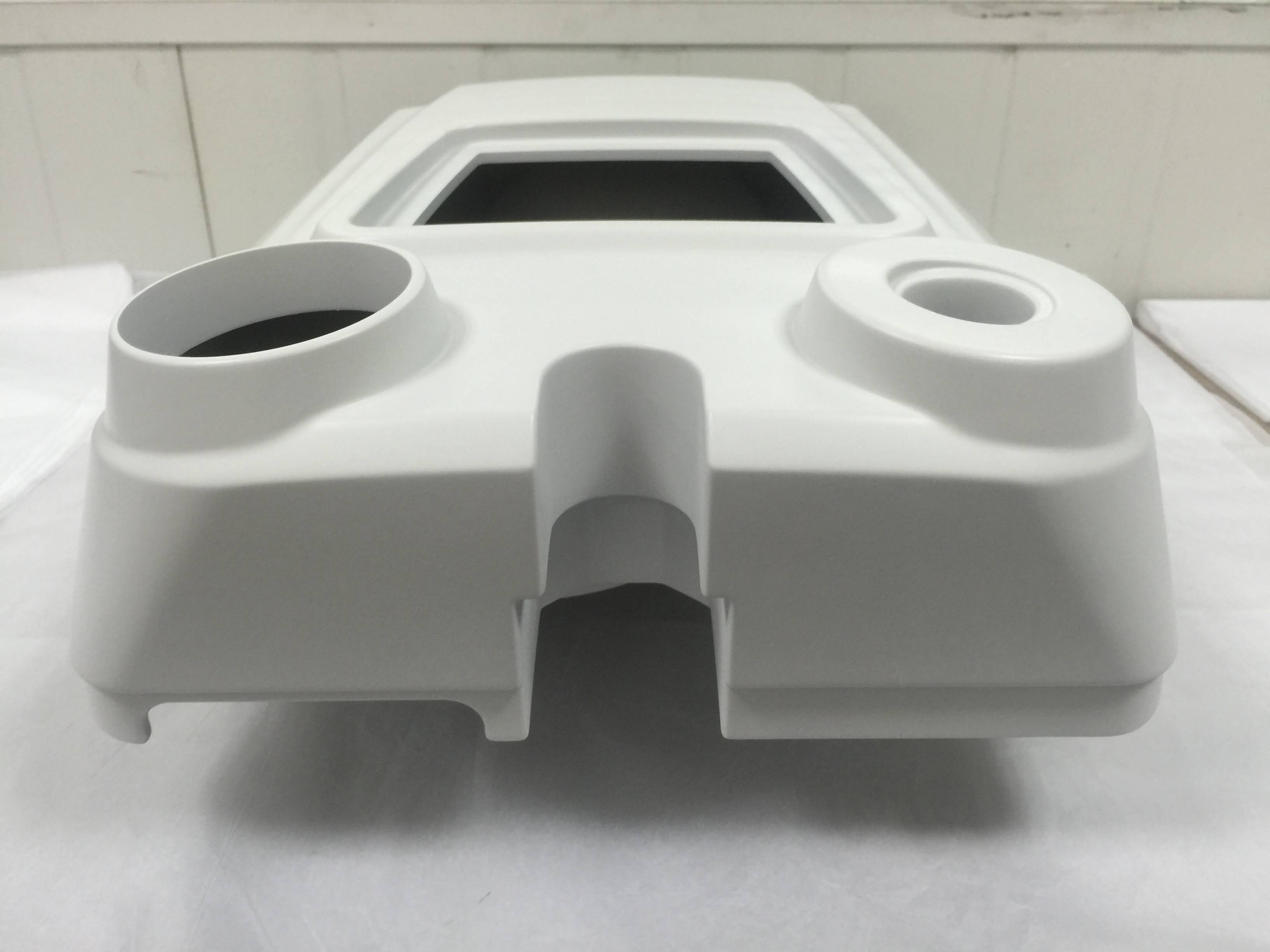

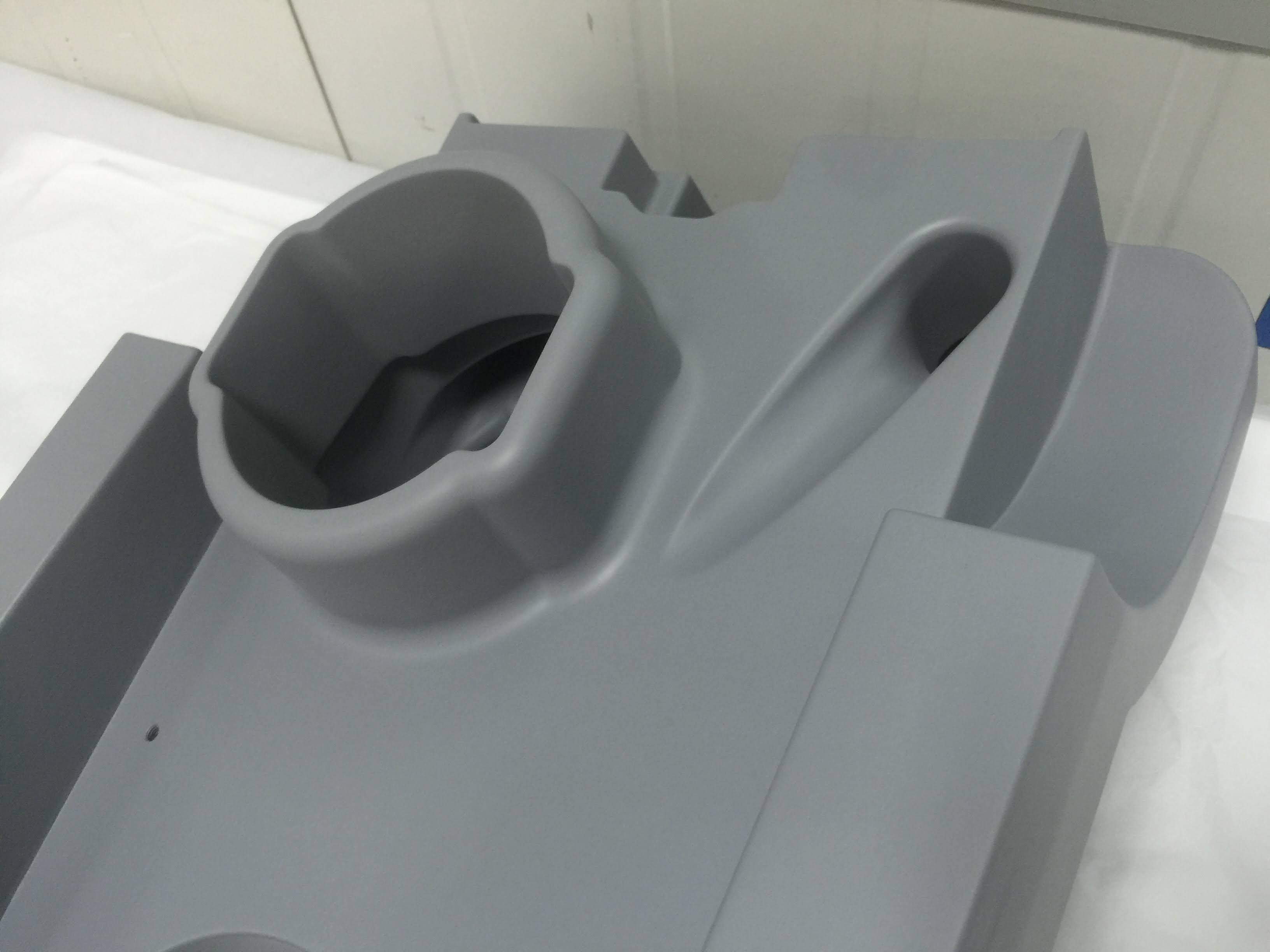

Key achievements included developing rotomolded plastic tanks that seamlessly integrated with metal frames, ensuring a cost-effective solution. Early client and manufacturer collaboration and balancing technical constraints with design intent were crucial for success. This new product line maintained Excentr’s robust appeal and set the stage for future product expansions.

Excentr

Industry

Cleaning services & equipment

My role

Industrial design lead

Discover

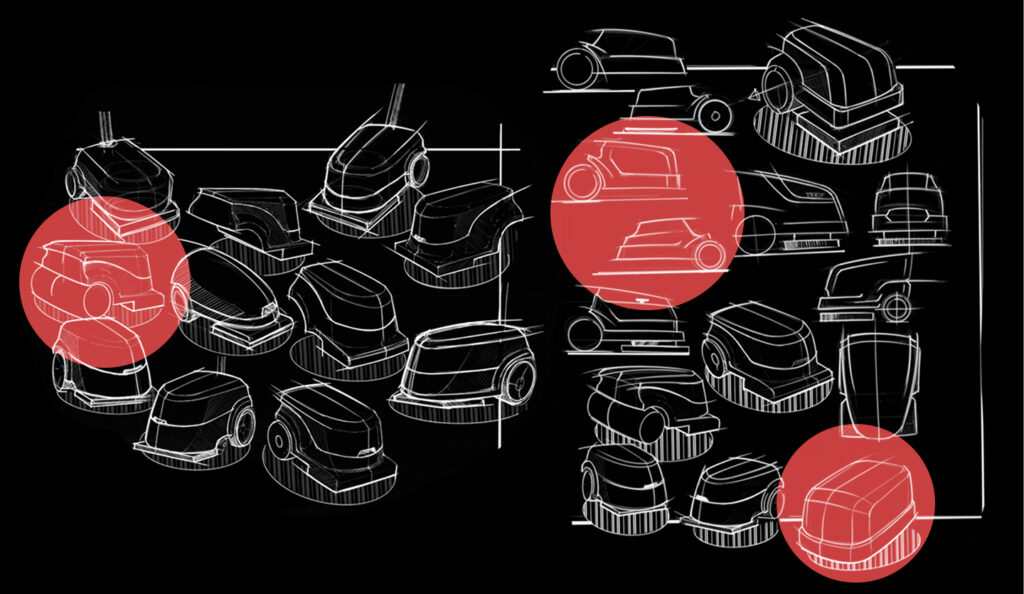

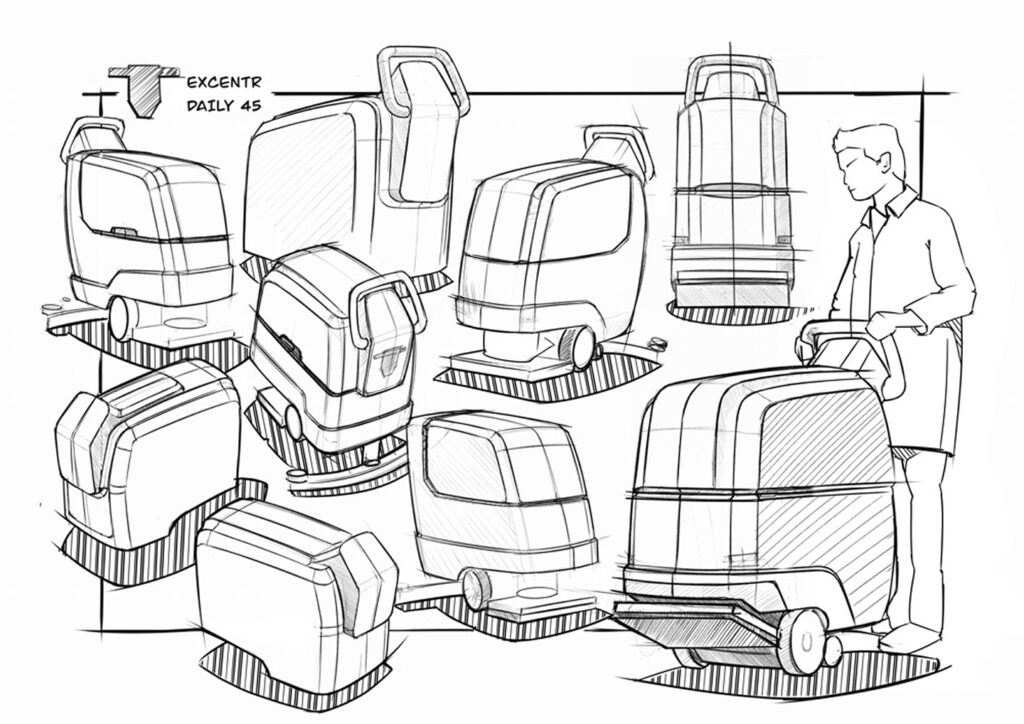

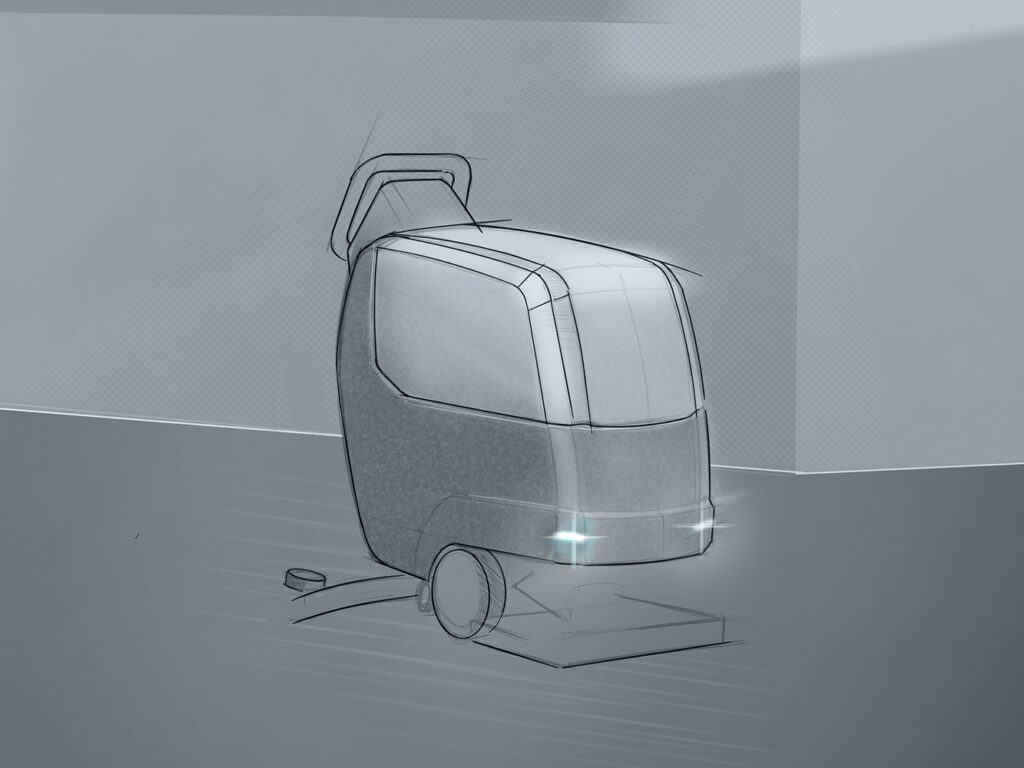

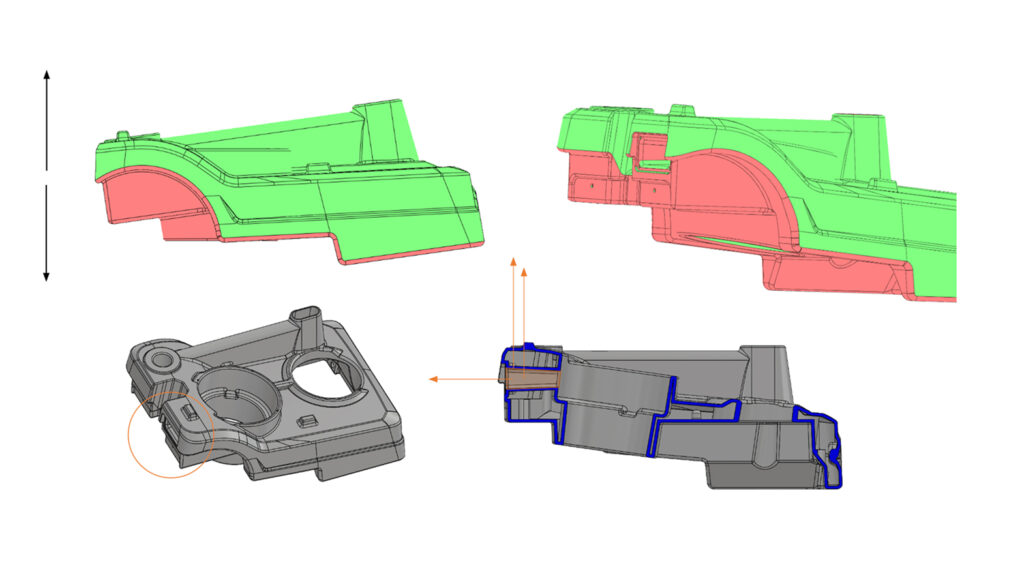

We started the project with a competitive analysis to understand the market landscape, existing products, and potential areas for differentiation. In parallel, I identified user needs and ergonomic challenges with current cleaning systems, uncovering opportunities to improve usability, handling, and maintenance. To support the design direction, I explored material and manufacturing constraints, specifically rotomolding, as a means to produce durable plastic parts

Design

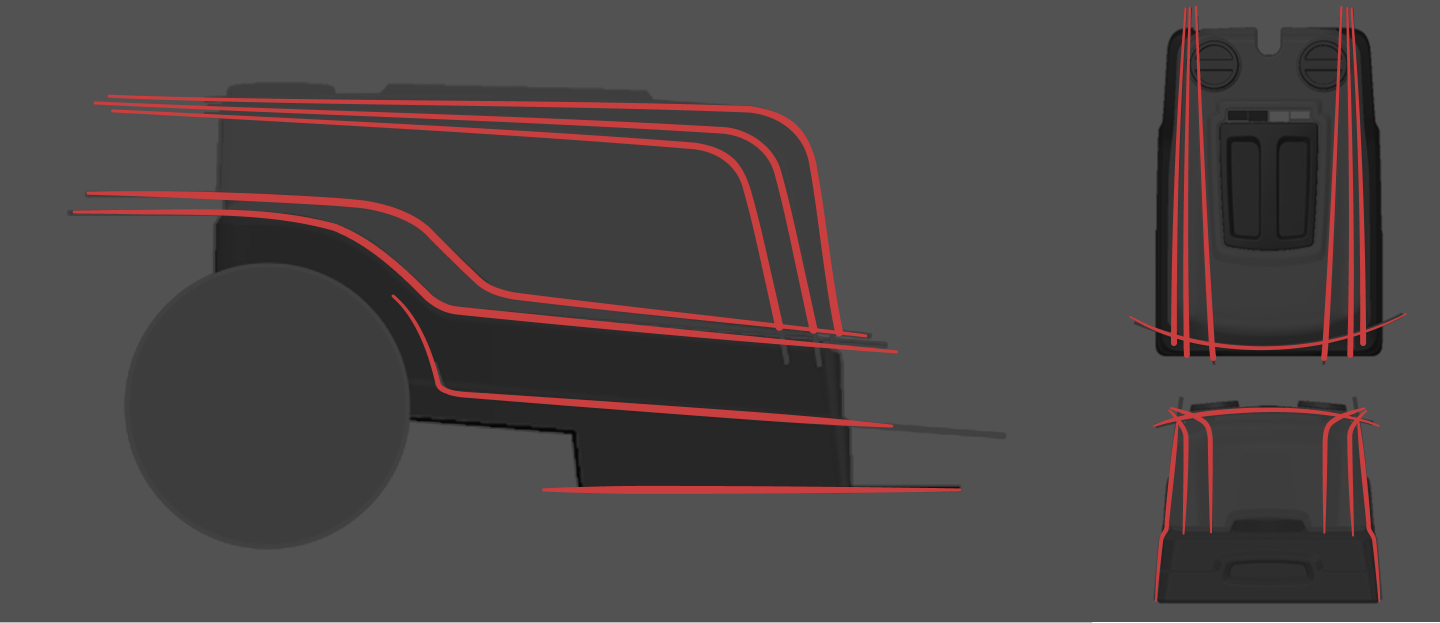

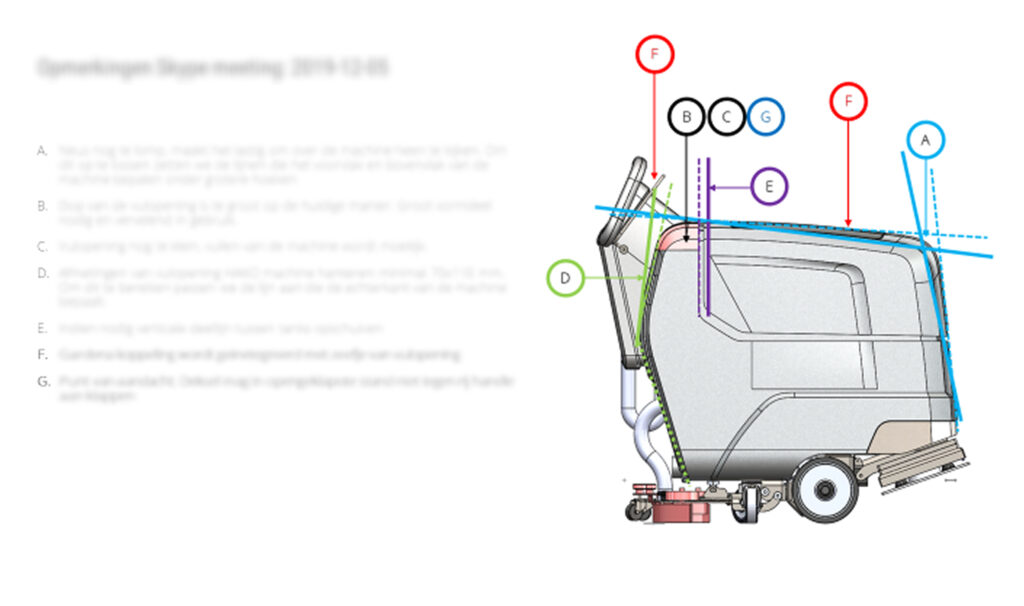

Throughout the process, I acted as a bridge between stakeholders, ensuring the design met both technical feasibility and visual requirements. I led the development of aesthetic and functional guidelines that aligned with Excentr’s brand identity as well as engineering constraints.

Throughout the process, I acted as a bridge between stakeholders, ensuring the design met both technical feasibility and visual requirements. I led the development of aesthetic and functional guidelines that aligned with Excentr’s brand identity as well as engineering constraints. To support a smooth collaboration with a long-distance client, I established clear and efficient ways to communicate design decisions and updates, using visual documentation and regular check-ins. Through multiple rounds of prototyping, we tested usability, structural integrity, and vacuum-sealing performance to refine the design.

Deliver

To support a smooth collaboration with a long-distance client, I established clear and efficient ways to communicate design decisions and updates, using visual documentation, regular check-ins, and annotated prototypes. Through multiple rounds of prototyping, we tested usability, structural integrity, and vacuum-sealing performance to refine the design.

We successfully delivered a new product line with integrated fluid tanks that maintained Excentr’s robust, professional aesthetic. The design was cost-effective and manufacturable, streamlining production while enhancing functionality. This work also laid the foundation for future product development and helped shape the next generation of Excentr’s lineup.